big advance in carbon capture technology could provide an efficient and inexpensive way for natural gas power plants to remove carbon dioxide from their flue emissions, a necessary step in reducing greenhouse gas emissions to slow global warming and climate change.

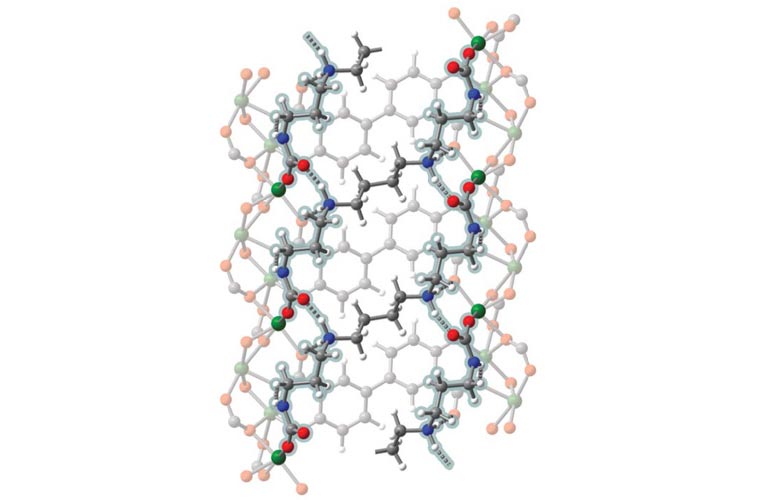

Developed by researchers at the University of California, Berkeley, Lawrence Berkeley National Laboratory and ExxonMobil, the new technique uses a highly porous material called a metal-organic framework, or MOF, modified with nitrogen-containing amine molecules to capture the CO2 and low temperature steam to flush out the CO2 for other uses or to sequester it underground.

The process uses low temperature steam to regenerate the MOF for repeated use, meaning less energy is required for carbon capture.

“For CO2 capture, steam stripping — where you use direct contact with steam to take off the CO2 — has been a sort of holy grail for the field.

It is rightly seen as the cheapest way to do it,” said senior researcher Jeffrey Long, UC Berkeley professor of chemistry and of chemical and biomolecular engineering and senior faculty scientist at Berkeley Lab.

The cost of scrubbing the emissions would have to be facilitated by government policies, such as carbon trading or a carbon tax, to incentivize CO2 capture and sequestration, something many countries have already implemented.

The work was funded by ExxonMobil, which is working with both the Berkeley group and Long’s start-up, Mosaic Materials Inc., to develop, scale up and test processes for stripping CO2 from emissions.

Low-temperature steam can strip out the carbon dioxide for sequestration, allowing the MOF to be reused to capture more carbon from power plant emissions.

“We were able to take the initial discovery and, through research and testing, derive a material that in lab experiments has shown the potential to not only capture CO2 under the extreme conditions present in flue gas emissions from natural gas power plants, but to do so with no loss in selectivity,” said co-author Simon Weston, senior research associate and the project lead at ExxonMobil Research and Engineering Co.

“We have shown that these new materials can then be regenerated with low-grade steam for repeated use, providing a pathway for a viable solution for carbon capture at scale.”.

Carbon dioxide emissions by fossil fuel-burning vehicles, electricity generating plants and industry account for an estimated 65% of the greenhouse gases driving climate change, which has already increased Earth’s average temperature by 1.8 degrees Fahrenheit (1 degree Celsius) since the 19th century.

Power plants strip CO2 from flue emissions today by bubbling flue gases through organic amines in water, which bind and extract the carbon dioxide.

A new technique could capture carbon dioxide from the emissions from such plants in order to sequester it underground and reduce the greenhouse gases responsible for climate change.

Department of Energy, discovered a chemically modified MOF that readily captures CO2 from concentrated power plant flue emissions, potentially reducing the capture cost by half.

They added diamine molecules to a magnesium-based MOF to catalyze the formation of polymer chains of CO2 that could then be purged by flushing with a humid stream of carbon dioxide.

A major advantage of the amine-appended MOFs is that the amines can be tweaked to capture CO2 at different concentrations, ranging from the 12% to 15% typical of coal plant emissions to the 4% typical of natural gas plants, or even the much lower concentrations in ambient air.

Mosaic Materials, which Long co-founded and directs, was created to make this technique available widely to power and industrial plants.

The new version uses four amine molecules — a tetraamine — that is much more stable at high temperatures and in the presence of steam.

“The tetraamines are so strongly bound within the MOF that we can use a very concentrated stream of water vapor with zero CO2, and if you tried that with the previous adsorbents, the steam would start destroying the material,” Long said.

They showed that direct contact with steam at 110-120 C — a bit above the boiling point of water — works well to flush out the CO2.

Steam at that temperature is readily available in natural gas power plants, whereas the 180 C CO2-water mix required to regenerate the earlier modified MOF necessitated heating, which wastes energy.

Reference: “Cooperative carbon capture and steam regeneration with tetraamine-appended metal–organic frameworks” by Eugene J.

Co-authors with Long, Kim and Weston are Joseph Falkowski from ExxonMobil; Rebecca Siegelman, Henry Jiang, Alexander Forse, Jeffrey Martell, Phillip Milner, Jeffrey Reimer and Jeffrey Neaton from UC Berkeley; and Jung-Hoon Lee from Berkeley Lab.